We often hear the word OEM and ODM from the businessman. What is OEM? and What is ODM? What’s the Difference between OEM/ODM? Let us show you: OEM VS ODM

As an importer, there is a higher chance that you’ve come across ODM and OEM. Nonetheless, these two terms are crucial in the manufacturing sector. The majority of the startup company lacks enough resources to manufacture their own products. In such situations, the companies opt to outsource their products from another manufacturing or production company. And that’s not all, there are also large scale companies that are well established but still rely on contract manufacturers due to the low cost of production.

It can be the outsourcing of the whole product or just part of it. This job is often given to contract manufacturers since they have the whole resources that these companies need. You, therefore, have to choose between two basic contract manufacturers, an ODM manufacturer or an OEM manufacturer. But what exactly are ODM and OEM manufacturers? Are there contrasts between them? So, let’s find out.

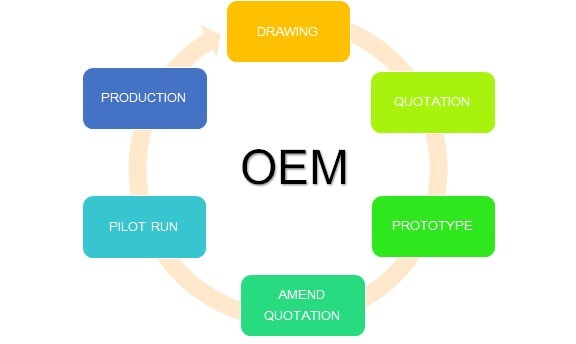

What is OEM?

OEM also referred to as Original Equipment Manufacturer is a term that is nowadays tossed around more often. This makes it’s meaning a little confusing and hard to understand. Usually, OEM is a type of contract or outsourced manufacturing. In simple terms, it’s a factory that is capable and also willing to engage in the manufacturing of products according to your preferred unique style as well as specification.

So when should you consider using OEM?

This is a simple yet tricky question. Some people might think they need OEM services like slight customization, but that’s wrong. The best time to engage with OEM company is when you need new tooling prior to production.

Typically, you will need personal R&D (Research and Development) first before engaging with OEM. This step involves research on the target market, specific design, and product engineering for electrical or moving components.

For better understanding, let’s say you are working on a new idea of smart office desks tops. Apart from providing you with a working surface, the desk has a smart top that functions like a PC. You can type, get online or even save soft copy office documents.

You have now taken your idea to the next step and have hired enough specialists to help you develop the design. Also, you have done market research and found a potential market for your product. And that’s not all; you have enough investment capital in place to bring your smart office desk into reality.

At this point, you only need someone to cater to production. With the design, capital and clear guideline on what you need, it’s time to engage an OEM factory. Using the capital and design documentation, the OEM factory will set up the production process and manufacture your product in large bulks to meet up the market demand.

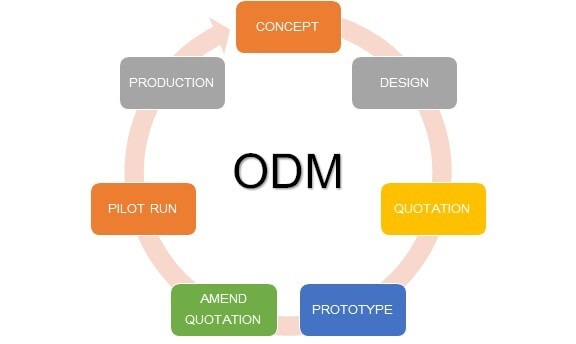

What is ODM?

ODM stands for Original Design Manufacturer. Similar to OEM, it’s a type of contract manufacturing but with a broader service scope. Apart from manufacturing services, ODM also provides services for product development and in some cases product lifecycle. However, the service scope depends on the ODM supplier you deal with and the extent of their capabilities.

So when should you consider ODM?

For better understanding, let’s say you are working on an idea about laptops. You’ve researched well and found a potential market for selling inexpensive laptops but with decent quality. Yes, you have all the ideas about the general design and some features, but what you lack is technical specifications and drawing. And your major concern is a device that will match your requirements.

In such a case, engaging an ODM manufacturer is the best option available. With ODM, all you will need to provide is the design and specifications of your idea. Alternatively, ODM manufacturing could be having similar products or ideas that can be tweaked to meet your specifications.

In either of the option, ODM will engage in both product development and manufacturing. Also, you have the option of branding the product so that it seems like you are the manufacturer.

OEM VS ODM

- Difference in Production

In OEM production, the buyers are usually interested in a particular component of a machine or a part crafted with a specific design. In most cases, the buyers are usually the source of the design and specifications. Such products undergo assembly and placed for sale in market under a given trademark by the buyer. The majority of these products under OEM production can be found in the market with price rates that are competitive.

While ODM companies, on the other hand, produce products that the buyers want. The only thing required from the buyer is an idea and particular features they need to be included. From there, the ODM Company comes up with the product’s technical design and specification. At times, the ODM Company usually has a similar product that the buyer wants. In such a case, they apply some minor customizations to meet certain needs of the buyer.

The advantage of opting for such suppliers is being free from expenses of doing personal R&D and also the acquisition of experts to take part in the technical bit of the product design and specifications. The majority of the buyers who choose ODM are small scale business owners who cannot meet the large investment required in using OEM business.

In terms of production, there are only two basic types of ODM companies, the white label, and the private label. White label products are those that are generic and sold using different types of brand titles by different retailers who buy them from ODM suppliers, while Private label products, on the other hand, are complete products bought from the ODM supplier by particular private retailers.

- Difference in supply

Both OEM and ODM manufacturers supply parts or a whole complete product. The difference comes in the product design and specifications. When dealing with OEM suppliers, the final product will be your own specifications, design, and requirement. Therefore, they are great suppliers if your target is a unique product that is in your brand name.

While ODM suppliers on the other hand, also supply complete products, but the credit of the end product belongs to the supplier. Therefore, the supplier can decide to sell similar products to other buyers, and this eliminates product uniqueness. In this case, you can also brand the product as your own but you will have to sacrifice uniqueness and ownership of IP rights.

Additionally, when you choose a special product design that ODM supplier has not dealt with before issues with quality and performance are bound to happen. And this is unlike OEM which guarantees quality no matter how complex or technical your chosen design maybe

OEM advantages

Total ownership and control of the intellectual property is the major advantage when you opt for OEM. Since you did personal research and development (R&D) by yourself the all the rights over the Intellectual Property are all yours.

Flexibility- through owning all the IP rights from using OEM, you will have a better bargain and flexible to shift to other OEM suppliers if need be. However, ensure strong protection rights on your IP to prevent copycats from stealing your unique design.

Better manufacturer quotes. Since your design and specifications package is so detailed after doing personal R&D and expert consultations, you will easily get better manufacturer quotes.

When you opt for OEM, there is a production of products with high quality at inexpensive rates but in bulk amounts. All the products undergo quality checks under OEM as per the manufacturer testing standards.

There is product uniqueness as you come up with specific designs and specifications that interest you. Also you own the IP rights of your products, thus protecting your products from copycats. And this gives your products a sharper competitive edge among its counterparts.

OEM disadvantages

To small scale businesses, OEM poses a major disadvantage. And this is mainly in the provision of detailed design and specifications package which is a requirement when working with OEM.

The limitation comes in providing the resources needed to come up with this package. Also, the hiring of experts to chip in and ensure the design accuracy and functionality may be too expensive. Thus most of the small scale businesses rely on ODM as a better alternative

OEM mainly deals with large scale production of products. To engage Search Company in the production of your products you must have a large and ready market to sell enough for future procurement of their services again.

The key reason for many companies to engage with OEM is the search for perfection. They are in need of products with top-notch quality to satisfy their market demand. But the major limitation is availability of a few OEM suppliers who can uphold such qualities.

ODM advantages

Using ODM saves you from a large upfront and full tooling fee. Thus it’s more convenient if you are a small scale, business owner.

There is no need for technical resources to develop design and specification package for your product, as ODM has the resources to handle this. Therefore, this provides you with plenty of time to figure out how to expand your target market and increase your product procurement.

You get charged with lower fees when dealing with ODM and you are exempted from product design as per your choice.

ODM is time-saving as you can procure ready and complete products from the manufacturers. This saves you from all the hustle of designing or searching for a credible manufacturer like in the case of OEM manufacturing.

With OEM products, uniqueness is what makes their products outstanding, but ODM products have a much sharper competitive edge, the price. Since the cost of production is relatively cheap in ODM, they can sell their products at a more affordable value to the consumers as compared to OEM product prices.

Fast marketing compared to OEM. This is because the products are readily available in bulk or take a very time to be manufactured. Unlike OEM where you have to spend more time coming up with a specific design from scratches and you also have to search for credible OEM before signing a production contract.

ODM disadvantages

With ODM, you lack the IP rights for your product; this leaves you with less bargaining power when negotiating for a contract. For example, you may be demanded by ODM to raise the product fee or even set the sale minimum volume for you.

In the worst-case scenario, the product IP could be from another company putting in you in a position of getting a lawsuit. Therefore, when engaging ODM in your business, take diligent and careful steps to avoid unnecessary risks.

There is tough product competition when you choose ODM manufacturers as the source of your products. This is because you have no IP rights over your products thus, the manufacturer can supply similar products to other buyers but under different brands’ names. to cut the story short, you will be among the many brands selling the same type of products but under different names.

Lack of uniqueness in your products, the products which you get from ODM are also made available to other buyers. This creates a market with the same products and lacks uniqueness. Hence there is no competitive edge that will make your product outstanding among others.

CONCLUSION

From the information above, you can now tell that the difference between these two contract manufacturers is the means of product development. OEM has a primary role of goods manufacturing alone. This means the buyer needs to come up with specific technical designs and specifications. This method can take a couple of months depending on the number of resources you have in place. Also, it will cost you a significant amount of investment.

And when dealing with ODM the entire R&D is done by the manufacturing company. You can only provide an idea of how you want the final product to look like. This method takes relatively a shorter period of time and saves you a lot of capital. However, you will not own the IP rights of your product.

Therefore, whether opting for either an ODM or OEM, the choice depends on your investment, goals, product and target market. However, the best advice is choosing an OEM rather than ODM. This is despite the lower cost of production associated with ODM. You need OEM because the benefits that come with owning the product IP rights when dealing with OEM outdoes the lower cost of production in ODM.